Updated:2024-10-31

Third-generation semiconductor materials, especially Silicon Carbide (SiC) and Gallium Nitride (GaN), show great market prospects in electric vehicles, renewable energy, industrial power supplies, military and aerospace, fast charging technology, wireless communication, consumer electronics, and other fields. These materials have advantages such as high thermal conductivity, high breakdown field strength, high saturation electron drift velocity, and high bond energy, making them perform well under harsh conditions of high temperature, high pressure, high frequency, and radiation resistance. Although these materials have significant performance advantages, their fast switching speed also poses considerable challenges for testing and measurement.

Case Introduction

In practical applications, the measurement of the Vgs of SiC MOSFETs is a technical pain point. The switching speed of SiC devices is very fast, which leads to a significant amount of harmonic energy in the high-frequency harmonic components. During actual development and debugging, oscillations in the Vgs signal of the upper tube are observed, and engineers are unable to determine the authenticity of the signal. This requires testing equipment to have high common-mode rejection capabilities even in the high-frequency range.

Testing Example

● Device Under Test: A high-power DC power supply project from a major power supply factory in Guangdong

● Test Points: Full-bridge circuit upper tube voltage waveform (Vgs) & upper tube Id current

● Customer Pain Point: When developing power supply products with SiC devices, traditional differential probes are used to measure the upper tube Vgs, resulting in signal oscillations that are difficult to analyze and locate problems.

Micsig Testing Solution

● Optical Isolation Probe MOIP Series: MOIP1000P

● High-Resolution Oscilloscope MHO3 Series: MHO3-5004

● Flexible Current Probe RCP Series: RCP600XS

Testing Site

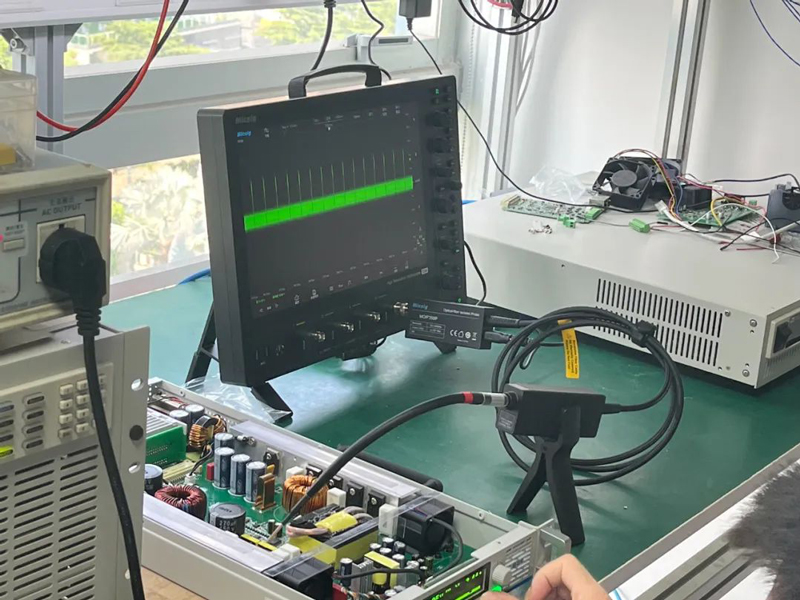

The following on-site testing image shows Micsig's high-resolution oscilloscope MHO3 series MHO3-5004, optical isolation probe MOIP series MOIP1000P, flexible current probe RCP series RCP600XS, and the device under test.

▲ On-site Testing Image

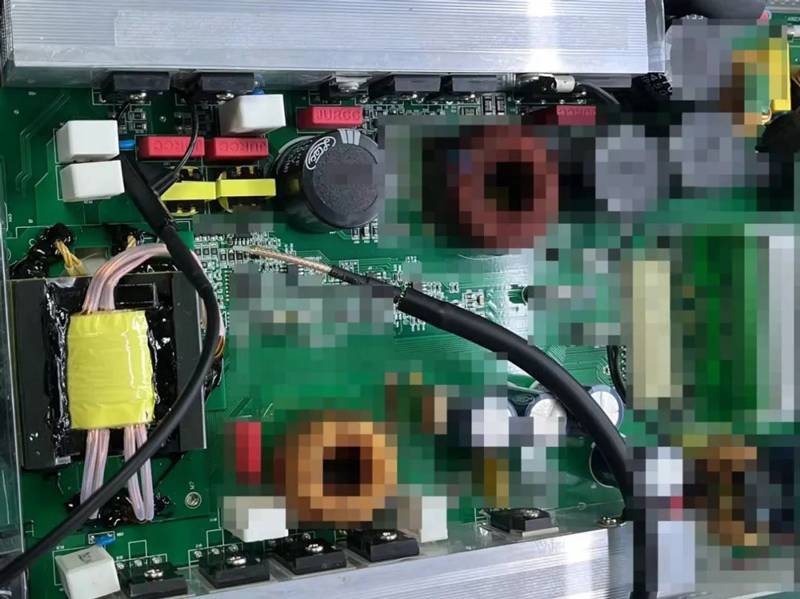

The following test point connection diagram shows the optical isolation MOIP1000P connected to the upper tube Vgs signal with MMCX coaxial cable, and the Rogowski coil RCP600XS monitoring the upper tube Id current signal by passing through the chip pins.

▲ Test Point Connection Diagram

The following oscilloscope display shows the upper tube Vgs and Id test waveforms, with channel 4 (green waveform) displaying the upper tube Vgs signal and channel 2 (blue waveform) displaying the upper tube Id current signal.

▲ Upper Tube Vgs and Id Test Waveform Diagram

Customer Feedback

Before coming into contact with Micsig's optical isolation probe, we used differential probes for testing. The waveforms did indeed show some oscillations when the upper tube was turned on/off; due to lack of experience, our engineers did not suspect the testing equipment and spent a lot of time changing circuits, adjusting parameters, etc., but the oscillation problem still existed. This time, using Micsig's optical isolation probe, we started with a try-it-out mentality, and the actual test results were very good. The waveforms at the test points were very similar to our theories, solving a major problem in our research and development.

Summary

Micsig (Micsig), based on its exclusive SigOFIT™ technology, has an optical isolation probe MOIP1000P with a common-mode rejection ratio as high as 180dB, still reaching over 100dB in the 1GHz frequency band. Using it can more effectively perform circuit testing and verification for power supply designs with SiC and GaN as core devices, allowing engineers to capture the real upper tube Vgs voltage waveforms, helping engineers accurately analyze whether their circuit designs meet the requirements, ensuring the high performance and reliability of the products. This not only improves their product quality but also strengthens market competitiveness. Micsig's innovative technologies and solutions provide strong support for more power supply design companies, jointly promoting the progress and development of the industry's technology.

About Micsig

Shenzhen Micsig Technology Co., Ltd. is a leading industry technology signal testing and measurement equipment research and development manufacturer and solution provider, a national high-tech enterprise, and a specialized and innovative enterprise. Micsig (Micsig) is committed to the research and development of cutting-edge technologies in the field of signal testing and measurement, especially in the field of oscilloscopes and oscilloscope probes, where we have always been at the forefront of innovation, being the pioneer of flat oscilloscopes and the leader in optical isolation probes.

We adhere to our mission and vision, starting from a professional standpoint, continuously breaking through technical boundaries, and helping every electronic field worker and their organizations to be more efficient and excellent.

Every one of our innovations is to break through the technical boundaries of products and explore new possibilities for industry trends.

The company's main products include oscilloscope series: high-resolution oscilloscopes, flat oscilloscopes, automotive diagnostic oscilloscopes, split-type oscilloscopes, oscilloscope probe series: optical isolation probes, high-voltage differential probes, flexible current probes (Rogowski coils), high-frequency AC/DC current probes, low-frequency AC/DC current probes, etc.